How is Manufactured Sand & Plaster Sand Redefining Construction from Rock to Result?

Introduction

With increasing environmental concerns and rapid urbanization, M-Sand (Manufactured Sand) and P-Sand (plaster Sand) are becoming a sustainable alternative in the construction industry. Manufactured Sand and Plaster Sand, created by crushing hard stones into fine particles, provide a reliable and environmental friendly alternative to natural river sand, which is both scarce and heavily exploited. Overusing natural sand has led to ecological damage, legal restrictions, and rising costs — making M-Sand and P-Sand a smarter, greener choice for modern infrastructure.

How Major Indian Companies Are Embracing Manufactured Sand and Plaster Sand Over Natural Sand for Sustainable Construction:

As the construction industry moves toward sustainable practices, many Indian companies are shifting from natural sand to M-Sand and P-Sand for their building needs. A range of equipment manufacturers supports this transition — with our Diamond Crusher perspective — supplying Vertical Shaft Impactors (VSI), Sand Master Fine cone crushers, and Sand Wash Equipment to help produce high-quality Manufactured Sand and Plaster Sand by crushing rocks into fine particles and removing impurities. With reliable performance and modern technology, such equipment enables large infrastructure and construction firms to reduce environmental impact while ensuring consistent, cost-effective project materials.

Government and Infrastructure Projects Leading the Way in M-Sand and P-Sand Adoption

Across India, leading infrastructure companies like Bangalore Metro Rail Corporation (BMRCL) rely on manufactured sand and plaster sand for their large-scale infrastructure work, ensuring material consistency and environmental compliance. Similarly, Tamil Nadu Housing Board (TNHB) has officially endorsed using Manufactured Sand and Plaster Sand in public housing projects, reinforcing its role in responsible and high-quality construction.

What is M-Sand & P-Sand, How It’s Made

Manufactured Sand (M-Sand) and Plaster Sand (P-Sand) are produced by crushing hard stones into fine, consistent particles that meet the standards of natural sand. Known for their strength, uniformity, and eco-friendly nature, M-Sand and P-Sand are ideal solutions for today’s construction needs.

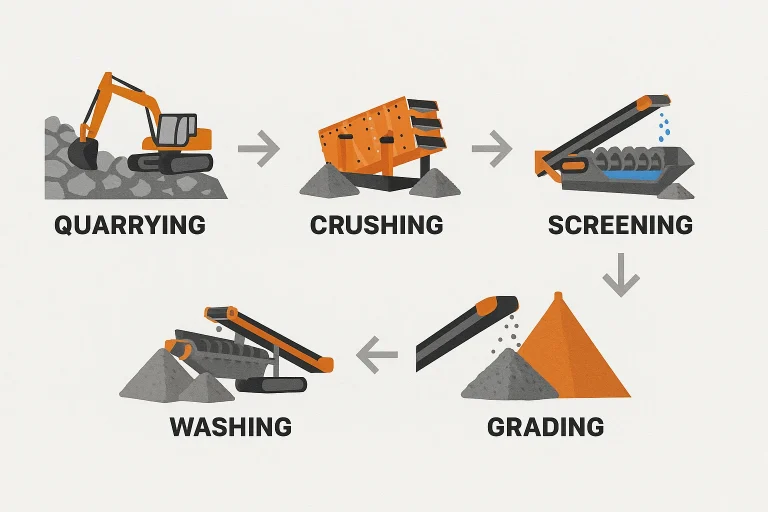

Manufacturing Process:

- Quarrying: Hard stones are collected from quarries.

- Crushing: The stones are crushed using machines like (VSI) Vertical Shaft Impactors and fine cone crushers such as Diamond’s Sand Master RC-44SH. These machines help break the stones into very fine sand-like particles.

- Screening: Crushed material is passed through screens to separate fine sand from larger particles.

- Cleaning: The sand is washed to remove dust, clay, and other impurities.

- Grading: The clean sand is sorted by size to meet construction standards.

- Quality Control: Ensuring each batch of Manufactured Sand and Plaster Sand is consistent, strong, and free from impurities to meet quality standards.

Why Manufactured Sand and Plaster Sand is a Better Alternative to Natural Sand

M-Sand and P-Sand are environmentally friendly as they help reduce erosion and habitat destruction caused by river sand extraction. It supports green initiatives by cutting down the need for river mining. With angular, cubical particles, M-Sand and P-Sand provide better grip and strength for concrete mixes. It has low water absorption, which reduces cement use and increases durability. Additionally, it is free from harmful impurities like clay and silt, making it ideal for construction.

Applications of M-Sand and P-Sand in Construction

- Concrete Mixes: Ideal for RCC, plastering, and bricklaying, providing superior bonding strength.

- Road Construction: Used in road layers due to consistent quality and grading.

- Ready-Mix Concrete (RMC) and Precast: Perfect for both industrial-scale and onsite projects.

- Water Conservation: Requires less water in concrete mixes, helping conserve water.

Industry Trends and Customer Benefits

The demand for M-Sand and P-Sand is growing due to urbanization and stricter environmental regulations. It is recognized by the government and RERA (Real Estate Regulatory Authority) for compliance with green building certifications like LEED (Leadership in Energy and Environmental Design) and GRIHA (Green Rating for Integrated Habitat Assessment). Using M-Sand and P-Sand offers benefits like cost savings, consistent supply, assured quality, and sustainability. It also ensures fast delivery with personalized service from companies like Diamond Crushers.

Conclusion

In summary, M-Sand and P-Sand provide significant advantages over natural sand, such as consistent quality, environmental sustainability, improved workability, enhanced strength, and cost-efficiency. With the growing demand in the construction sector, M-Sand and P-Sand are becoming a vital component in modern construction practices. At Diamond Crushers, we offer a wide range of construction materials and solutions tailored to meet your needs. Reach out to us today to explore the full range of possibilities we can provide!

FAQs:

Manufactured Sand (M-Sand) and Plaster Sand (P-Sand) are eco-friendly substitutes for natural river sand, created by crushing durable materials such as granite and construction waste for use in building projects.

Yes, M-Sand and P-Sand is more eco-friendly than river sand because it doesn’t harm rivers.

Yes, it reduces cement and water use, lowering construction costs.