The Ultimate Handbook for Jaw Crusher Maintenance and Repairs

Introduction

The story of jaw crushers began in the 1850s when Eli Whitney Blake invented the first jaw crusher to help break down rocks for building roads. His invention changed how heavy materials were crushed and laid the foundation for modern crushing equipment. Over the years, jaw crushers have become an essential part of the mining, quarrying, and construction industries worldwide.

At Diamond Crushers, we have been part of this journey for more than 50 years. We started with a simple goal — to build strong and reliable jaw crushers. Today, we are proud to be one of the top most manufacturers and highest sellers of jaw crushers in India. Our machines are trusted for their strength, long life, and excellent performance.

With such an important machine at the heart of our operations, keeping it in peak condition is crucial. In this guide, we’ll walk you through simple maintenance tips and repair practices that will help you maximize your jaw crusher’s life, ensure smooth performance, and avoid costly downtimes.

Why Regular Maintenance Matters for Jaw Crushers

Routine maintenance is important to keep your jaw crusher working properly. If you ignore regular checks, important parts like the jaw plates can wear out faster. It’s better not to wait for big problems like cracks or holes. Minor signs like loose parts or material sticking to the crusher need quick attention.

It also helps avoid sudden breakdowns and keeps your machine running longer. Good maintenance protects your investment and makes sure your jaw crusher stays strong for many years.

At Diamond Crushers, we have been part of this journey for more than 50 years. We started with a simple goal — to build strong and reliable jaw crushers. Today, we are proud to be one of the top most manufacturers and highest sellers of jaw crushers in India. Our machines are trusted for their strength, long life, and excellent performance.

With such an important machine at the heart of our operations, keeping it in peak condition is crucial. In this guide, we’ll walk you through simple maintenance tips and repair practices that will help you maximize your jaw crusher’s life, ensure smooth performance, and avoid costly downtimes.

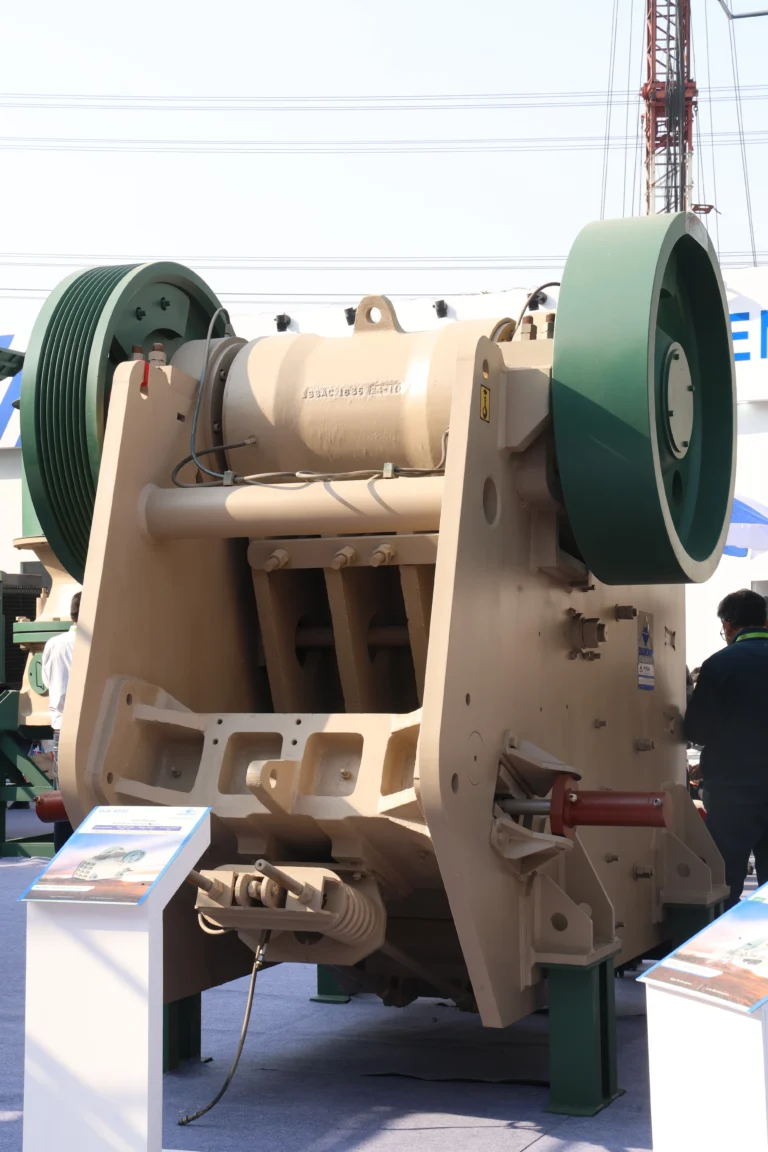

Key Areas to Inspect and Maintain

Make a Maintenance Checklist

Having a checklist makes jaw crusher maintenance easier and faster. It helps you remember what to check and keeps the work safe and organized. List all parts that need inspection and mark them once done to avoid missing anything.

Lubricate Moving Parts

Lubricating the jaw crusher’s components minimizes friction and helps prevent damage. Use a grease gun or oiler to apply grease to important parts like the eccentric shaft and main shaft. Regular lubrication keeps the machine running smoothly for a longer time.

Understanding Pitman Bearing Failure

The Pitman Bearing plays a crucial role in moving the jaw plates to crush stones. Without proper lubrication, it may suffer from excessive wear due to the high pressure during crushing. A damaged Pitman Bearing can cause operational failures and stop the crusher. Regularly checking and adjusting the bearing helps keep the crusher running properly and avoids costly repairs.

Inspecting Other Key Components

To keep your jaw crusher working properly, it’s important to check a few extra parts regularly.

- Discharge Port: Regularly check and clear blockages to keep material flowing smoothly.

- V-Belt: Inspect the belt tension; tighten it if it’s loose to avoid slipping.

- Eccentric Shaft: Make sure the shaft bush is secure; repair or replace if it’s loose.

- Flywheel Wedge: Confirm the wedge is in the correct position to prevent crushing issues.

Common Problems and How to Fix Them

- Temperature Difference: If one bearing is much hotter than the other, it could mean damage.

- Unusual Noises: Strange sounds from bearings usually point to internal faults.

- Toggle Plate Adjustment: Adjust the support pad or wedges to set the correct output size.

Pick jaw plates that match the material you are crushing. Stronger plates are needed for harder rocks. Using the wrong jaw plates can cause faster damage and lower performance. Always check if the teeth of the jaw plates fit correctly, as the wrong alignment can cause uneven damage. Tighten all bolts and nuts to prevent vibrations. Look for cracks or flat spots. If more than 80% of the plate is damaged, replace it to avoid sudden breakdowns.

At Diamond Crushers, we’re here to help. Our Spare Parts Division ensures quick support and provides quality parts to keep your crushing machines working at their best.

Conclusion

In conclusion, maintaining your jaw crusher helps improve its performance and reduces the risk of unexpected failures. Prompt repairs and proper maintenance not only enhance the equipment’s lifespan but also improves its overall performance.